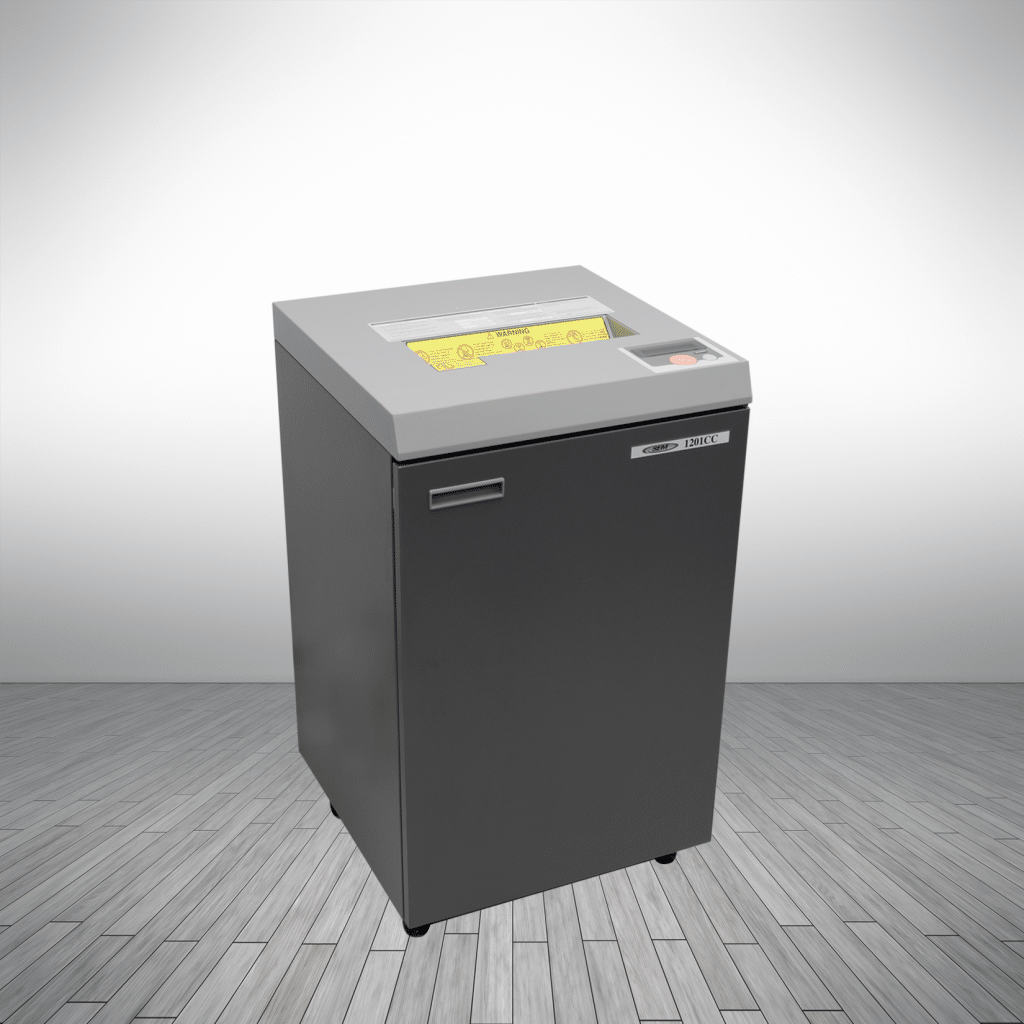

Shredding a hard drive just like a paper shredder, how can that be? That’s right, when it comes time to dispose of old hard drives that contain millions of pages of data and information, they can be shredded into strip cut pieces just like a paper shredder. The question is which hard drive shredder best meets an individuals or company’s needs?

Which Hard Drive Shredder is Best?

In order to determine which hard drive shredder is the best solution, a few things must be considered. What is the volume of drives needed to be destroyed? What is the security level required? Do we have the proper power to operate the system? Once these are answered, the search can begin.

SEM offers a variety of hard drive shredders that answer all of these questions. From a low volume, small footprint, office-like system with standard single phase power like the SEM Model 0300 to a larger, industrial size, high volume system with 3-phase power like the SEM Model 0304, SEM has a solution to meet your needs.

Prioritize Your Needs

If SECURITY is your most important priority – the smaller the better. As such, a .75” strip cut is more desirable than 1.0” or 1.5”. Model 0304 have the capabilities to produce all three strip cut sizes.

If VOLUME is more important – any of the systems with a shred size of 1.5” produce the higher volumes that range from 500 to 3500 hard drives per hour.

POWER –The Model 0300 requires standard 120V -20Amp power while the remainder of systems require 3-phase power at 208, 230 or 460V. Therefore, your facility must be able to accommodate this power.

SPACE – The 3-phase power units that can shred high volumes require enough space to accommodate the shredder and the discharge conveyor. A collection container to accept the shredded drives must also be considered. As such, the facility must have enough room to handle these configurations.

What to do With Shredder Drives

Hard drives contain a variety of precious metals such as gold, copper, aluminum, and more. Once the drives are shredded, these can be sold to recyclers who have the capability to separate the metals through a smelting process. When gold prices are up, it doesn’t take much to make these shredded drives very valuable. At the time of this report, a shredded hard drive had a value of about 50 cents per drive.

SUMMARY:

If you have need to dispose of hard drives or similar items such as cell phones, blackberries, etc., an SEM hard drive shredder is a clean, simple to operate, highly effective solution. And with so many options available from SEM, there’s always one that fits your needs.