Tuesday, November 28, 2006

Masters of Destruction

Westboro company specialist in sensitive data

By Martin Luttrell TELEGRAM & GAZETTE STAFF

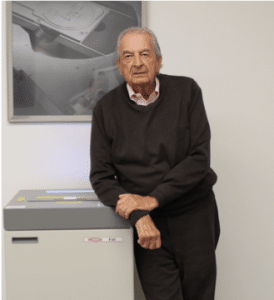

For decades, the federal government and private businesses have used Security Engineered Machinery equipment to shred paper records, and more recently, computer drives, CDs and other electronic records.

And with sensitive information remaining on old computer hard drives, cell phones and BlackBerries, the Walkup Drive company is expanding into full-service data destruction for clients that want secure handling and destruction of their electronic devices.

Founded in Millbury in the late 1960s, SEM employs 44 and is the largest manufacturer of document- and electronic-disintegration equipment, with its shredding and disintegration machines in use by the Departments of Defense and Homeland Security, in State Department embassies around the world and by the U.S. Postal Service. More than 400 central banks worldwide use the company’s equipment for shredding old currency.

The federal government has been the biggest customer, but private industry is catching up as accidental releases of sensitive data make headlines.

SEM showed a reporter a room the company renovated from warehouse space that now houses machines for shredding computers and other electronic data storage devices. Computer hard drives, keyboards and towers moved up an inclined conveyer about 12 feet, where they were dropped into a hopper and ground into pieces an inch or two in size.

“The federal government is light years ahead of the private sector in security,” Mr. Dempsey said. “A lot of companies have paper shredders. But what happens to a CD or diskette? The government has been doing this for years.

“There is not a piece of equipment here that has not been cleared by the NSA (National Security Agency) for classified destruction,” he said. “Not all companies will spend $25,000 for a machine like this. That’s where this service comes into play. We have people that walk in with one hard drive, and we’ll destroy it and let them witness it.”

Clients who ship their items to SEM can even watch over a designated Web site as their computers or other items are destroyed; some 17 video cameras mounted in the ceiling, and more in the hoppers of the machines, beam images of the process.

“We send it premium freight so it can be tracked door to door,” he said. “Some clients put GPS (global positioning system) inside so they know where it is all the time.”

SEM puts bar codes on the hard drives slated for destruction so the customer can document the process, he said.

Inside a locked cage along one wall were several cases and military transport containers holding computer components slated for destruction.

“We look at ourselves as being in the security business,” Mr. Dempsey said. “We approach our shredding as a security division. We’re interested in hard drives, cell phones, DVDs, CD-ROMs and unconventional items,” including X-rays, he said.

Mr. Dempsey held pieces of a computer that had gone through a disintegrator, noting that they were a couple of inches in length. Some clients require that their magnetic data items be in smaller pieces, and those go into another machine, which tears them into pieces an eighth of an inch in diameter.

He pointed out that a piece of a CD that goes through an office shredder contains much more information than would be printed on a piece of office paper. Sophisticated equipment could be used to retrieve that information, along with data thought to be deleted from hard drives, cell phones and other electronic devices, he said.

In addition to tearing electronic data equipment into small pieces, SEM can also use a method known as degaussing, or erasing electronic data, before destroying it, he said.

“From a private-industry point of view, degaussing is all you need to do,” Mr. Dempsey said. “What we’re now seeing in Fortune 500 companies is that they’re defaulting to the federal government’s standards that are NSA-approved.”

He said that when companies consider the damage that could result from sensitive information being compromised, data security is increasingly in demand.

“We bring credibility to the table,” he said. “We’re in the security business. Quite a few of our employees have obtained clearances. They get a background check. We do DOD work. Anyone in this room would need a clearance,” he said, referring to those working in the company’s destruction service.

All employees are drug-screened and go through background and criminal checks, he said.

Mr. Dempsey would not talk about the private company’s finances, but said it made $20,000 from its destruction services two years ago and $300,000 this year. The demand is growing, he said.

“We’ve seen an explosion from companies with financial and health care” records. “With some of the information compromises that have been in the press, they’re adapting. We know how to deal with those issues. …Crisis management is not proactive. That happens after data has been compromised.”

He said the company spent 13 months renovating the area now used for destruction services. Now, he wants the operation to be deemed a secure facility so that it can take on the federal government as a client. That could take another year, he said.

“So far, we’ve been under the radar, doing this as a favor for our clients.”