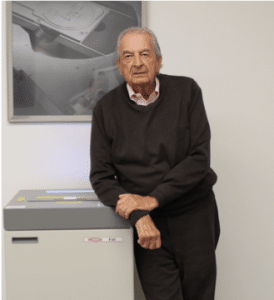

WESTBORO, MA — The SEM Model SSD1-HS from Security Engineered Machinery reduces solid state devices to waste particles of .5mm squared or less and meets DIN 66399 Standard E-7; smaller than the NSA requirement for sanitization of SSD devices per NSA/CSS EPL 9-12. Absolute destruction through repetitive high speed cutting of memory media ensure all data is properly sanitized.

Storage media is continuously cut until it is small enough to pass through a customer selected waste sizing system to meet customer’s security level or a specific DIN Level. Items that can be destroyed in the Model SSD1-HS include solid state boards, RAM, smart phone / cell phone components, SIM cards, USB flash drives, compact flash and even optical discs. The Model SSD1-HS is a compact, self-contained destruction system with all components housed within a custom enclosure for maximum sound, odor and dust control.

The Model SSD1-HS destruction capacity is dependent on the media being destroyed and the customer selected sizing screen.

An ergonomic operator interface allows easy viewing and control of all machine functions. The Model SSD1-HS features an interlocked feed slide with integrated feeding protocols ensuring proper metering of media through the data sanitization process. Safety interlocks prevent operation when any safety guard or panel is not in place or waste disposal is required. An air filtration system consisting of a carbon pre-filter and HEPA filter is also included.

Security Engineered Machinery, SEM, is an innovative designer and manufacturer of data-destruction equipment located in Westboro Massachusetts. SEM supplies mission critical EOL equipment to the US Federal Government including the DoD and other intelligence agencies, as well as large multinational datacenter operators. SEM’s engineering staff is available to assist customers with special products and systems that will sanitize any media / material down to stakeholder required sanitization levels such as high volume central destruction systems used by nationally recognized commercial banks and healthcare organizations. Areas of expertise include the destruction of hard drives and other mixed media and heavy-duty, high-capacity shredders for recycling applications.

For more information, contact James T. Norris, Norris & Company, 264 Bodwell Street, Avon, MA 02322 Tel: (508) 510-5626, FAX: (508) 510-4180, E-mail: jim@norrisco.com