Electrical Requirements

When it comes to the electrical requirement of SEM products it’s best to know that SEM’s equipment can be broken into two categories: out-of-the-box solutions and custom engineered solutions.

Out-of-the-box solutions

SEM’s out-of-the-box solutions are engineered to be “plug-and-play” ready. These units are generally standalone boxes with voltages that are standard in most countries. Examples include 110V/1-ph/60Hz or 220V/1-ph/50Hz. Only single phase units are considered plug-and-play ready. Even in these cases, however, SEM must verify voltage. Certain units, even in single phase, require a dedicated outlet in order to run.

Additionally, SEM needs to validate the power available in the destination location to which the machine is being shipped in order to ensure the unit will have the proper cable and electrical components prior to shipping.

Additionally, SEM needs to validate the power available in the destination location to which the machine is being shipped in order to ensure the unit will have the proper cable and electrical components prior to shipping.

An example of this would be a machine ordered in the United States and shipped internationally to a location in the UK. If SEM took the US order based on the information at face value, we would ship a 110V/1-ph/60Hz machine. When it arrived in the UK, the unit would not be able to operate and simply switching the plugs would not work as well. The motors on each unit are developed to clock at a specific frequency, so if you took a machine with a 60Hz frequency and ran it in the UK, you could damage the motor over time due to running at the incorrect frequency of power. The internals of the unit are voltage specific, so we cannot just swap the plug to change a unit.

Custom engineered solutions

SEM’s custom engineered solutions are machines that are built to the specifications of end user requirements. This includes voltage considerations at the site. In the cases of these types of machines, which typically use 3-phase power, voltage confirmation is required prior to quote generation. This is a requirement because 3-phase powered motors have different costs associated with them, and SEM needs to ensure we are equipping you with not only the machine that will meet all destruction needs, but also one that works with the power available at site.

Typical 3-phase power in the US is 208V/3-ph/60Hz, 230V/3-ph/60Hz, and 460V/3-ph/60Hz. Internationally, 3-phase power can include, but is not limited to, 220V/3-ph/50Hz, 380V/3-ph/50Hz, 400V/3-ph/50Hz, and 575V/3-ph/60Hz (Canada).

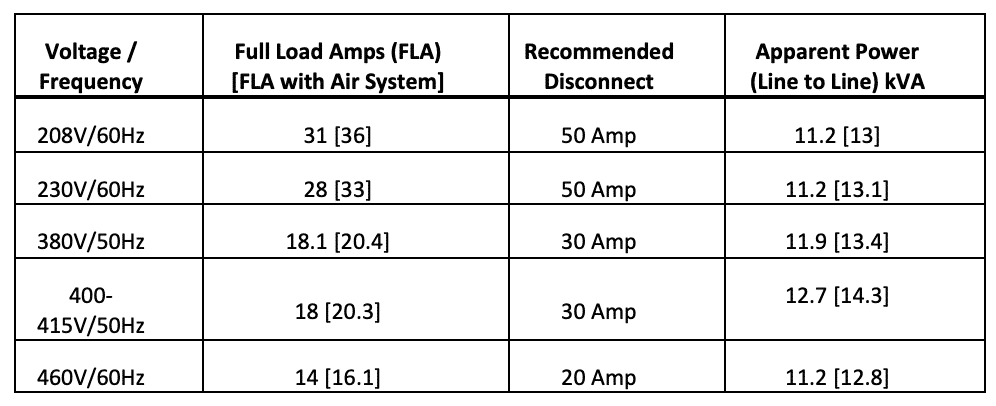

Since having additional power drops made available at sites is both costly (tens of thousands of dollars) and timely (can take months based on your provider), SEM always recommends that a licensed electrician reviews the SEM operator’s manual for the machine you plan to purchase and reviews the voltage charts with the recommended disconnects, Full Load Amps (FLA), and Apparent Power (KVA). See example:

SEM will confirm the voltage of the machine at the time of order, in writing, and process the fabrication or shipment of any order. If equipment installation is required on site, we will again confirm the voltage of the machine ordered and confirm the site has the power ready prior to dispatching technicians to install the equipment. In addition, for disintegrator installations, we want to make sure electricians are staffed on-site during the install and working directly behind our technicians to complete the install in a timely manner. If not, it can cause a return trip, adding cost.

Of course, if you have any other questions on electrical requirements, feel free to reach out to us at contact@semshred.com, 800.225.9293, or chat with us right here on our site!